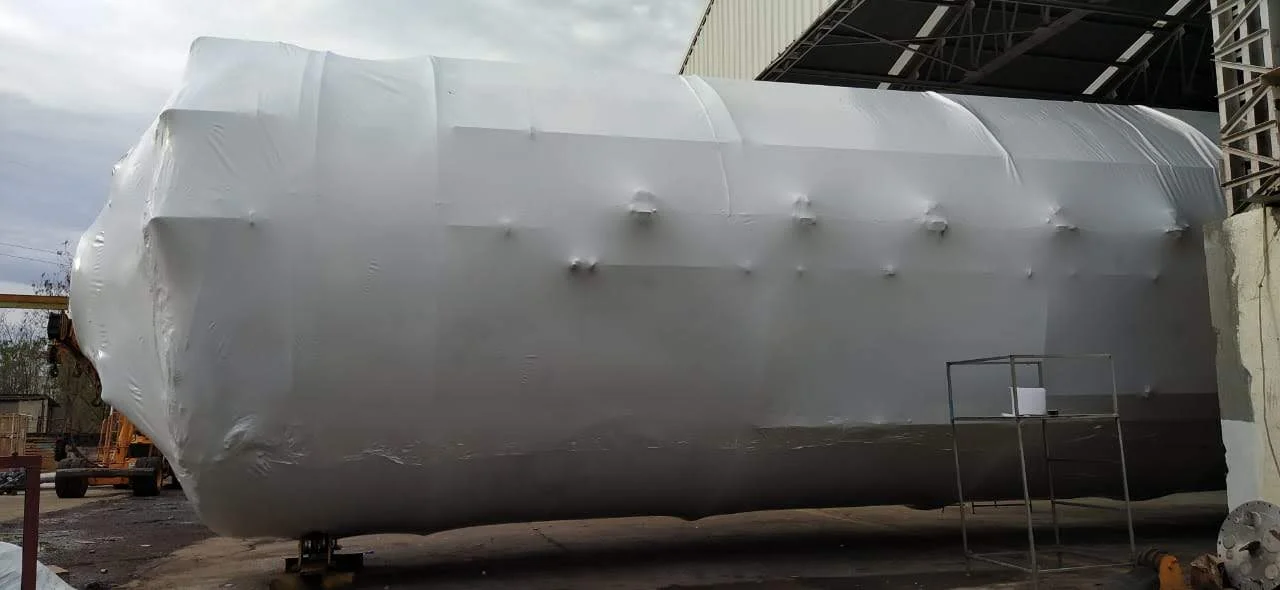

Our innovative shrink solution offers unparalleled adaptability, ensuring seamless wrapping for projects of any size or complexity. From all ongoing machinery to large industrial structures, Dr. Shrink+ products provide unmatched flexibility, durability, and protection for longer period.